In today’s logistics environment, supply chains have become increasingly complex and dynamic. There is an increasing demand for supply chain visibility, to allow for efficient shipment processing and planning. One of the most common ways to enable visibility is through container tracking.

Container tracking is the ability to locate a shipping container’s position and track other relevant types of shipping information through references such as a bill of lading, container or booking number.

There are two main ways to track a shipping container. You can track a container through vessel data provided by an Automatic Identification System (AIS) or through Container Tracking Devices (CTDs) that are installed on shipping containers at the time of departure.

In this article, we’ll be exploring the topic of container tracking by explaining how this works, providing a list of common container tracking statuses, how and where to track containers, as well as the benefits and limitations of container tracking.

Here’s an overview of the content that we will cover:

- How It Works

- List of Tracking Statuses

- How to Track Containers

- Where to Track Containers

- Benefits of Tracking

- Limitations of Tracking

How Does Container Tracking Work?

The two most common ways to track shipping containers is through vessel data via AIS or container data sent through container tracking devices. Let’s explore them in a little more detail.

1. Tracking Containers With AIS Data

By far the most common way to track shipping containers is by using a carrier’s website or container tracking service providers that receive vessel data through a vessel’s Automatic Identification System (AIS).

In the year 2000, the International Maritime Organization (IMO) made it mandatory that all vessels with a gross tonnage of 300 tons or more, require an AIS transponder.

These AIS transponders send a vessel’s location (latitude and longitude information) to AIS base stations via GPS satellites. This allows carriers and other websites to track a container’s location, as they have assigned containers to a particular vessel.

2. Tracking Containers Using CTDs

Another way of tracking shipping containers is by installing a Container Tracking Device (CTDs) at the time of loading or departure. This device is typically installed inside the shipping container and can provide location data based on GPS coordinates.

These container tracking devices also measure other types of data, such as temperature, impact, theft, weather and movement. As these trackers are attached directly onto containers, they provide more accurate data, as it doesn’t solely rely on vessel information.

As there is a cost to installing these units, container tracking devices are most commonly used for high-value cargo or when shipping to high-risk areas.

List of Container Tracking Statuses

Most container tracking services are able to provide information about the shipment and assess its last milestone through its last known location. Here are some of the most common container tracking statuses:

- Port of Loading (POL) – The port of loading where the container was loaded on the vessel. This is also sometimes called the origin port.

- Container Gate In – The date and time the container was gated into the port of loading.

- Estimated Time of Departure (ETD) – The estimated departure time of the vessel from the port of loading.

- Actual Time of Departure (ATD) – The confirmed departure time and date from the port of loading. This is also known as the ‘Shipped on Board’ date.

- Transhipment Port (T/S) – The location of the port where the feeder vessel will transfer the container onto the mother vessel for the final destination.

- Arrival at Transhipment Port – The date and time that the feeder vessel has arrived at the transhipment port

- Departure at Transhipment Port – The date and time the mother vessel has left the transhipment port.

- Port of Discharge (POD) – The port of discharge is the port where the container will be unloaded from the vessel. This is also known as the destination port.

- Estimated Time of Arrival (ETA) – The estimated date and time of arrival at the port of discharge.

- Actual Time of Arrival (ATA) – The actual date and time the vessel has arrived at the port of discharge.

- Container Gate Out – The date and time the container was gated out of the port of discharge.

How to Track Containers

Most, if not all, carriers enable container tracking via their own website. There are also other ways to track shipping containers, for example through 3rd party container tracking websites or through mobile applications.

In order to track shipping containers, you’ll require a reference number. A valid reference number would most commonly be a container number, bill of lading number or a booking number.

Here are the ways in which you can track shipping containers using examples of three different carriers, with container, bill of lading and booking numbers.

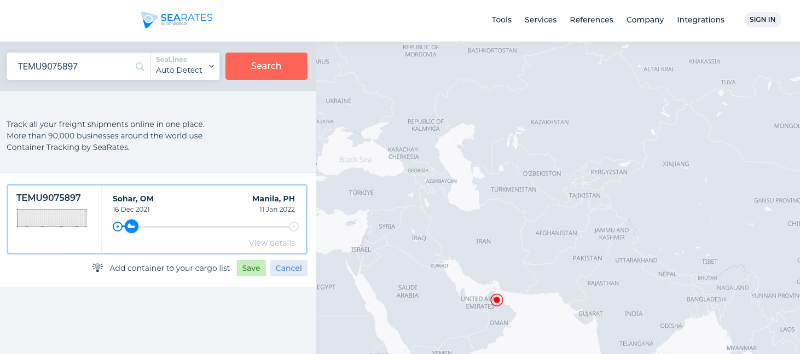

1. Track Containers with Container Numbers

One of the most common ways to track a container is with the container number. Shipping lines assign containers to specific vessels, which position they are able to track (through an AIS transponder).

This allows them to identify at what stage of a shipment the container is and what its latest tracking status was. Try using the link below by inserting the container number, selecting the container number button and searching.

Take note that this also works when using third party container tracking websites, as they are able to obtain container information from carriers through an Application Programming Interface (API) or similar methods.

- Carrier: Evergreen Marine

- Tracking Website: Tracking website link

- Container Number: TEMU9075897

2. Track Containers with Bill of Lading Numbers

You’ll also be able to track shipping containers on carrier websites using a bill of lading number. Carriers associate a particular shipment with a bill of lading number and similarly assign all the associated containers with it.

You can try this by selecting the BL option and inserting the sample bill of the lading number below. You’ll then be able to see the latest tracking events for all of the containers associated with the BL number.

- Carrier: OOCL

- Carrier Website: Tracking website link

- BIll of Lading Number: 2565226270

- Container Number: OOLU790613

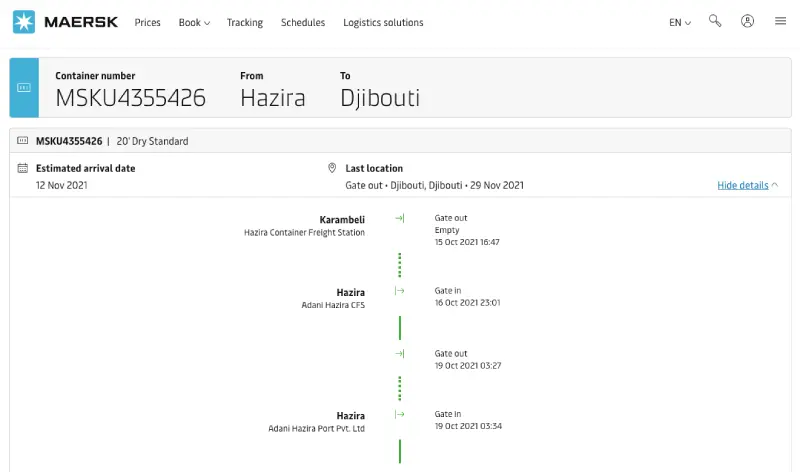

3. Track Containers with Booking Numbers

Similar to bill of lading numbers, carriers also use tracking numbers to assign containers. This means that you’ll be able to track shipping containers using a carrier’s booking number.

Take note that this must be the shipping line’s booking number and not the freight forwarders booking number, unless you check through the freight forwarders tracking website.

- Carrier: Maersk

- Carrier Website: Tracking website link

- Container Number: MSKU4355426

Where to Track Containers?

There are various ways to track shipping containers. While most carriers and freight forwarders offer container tracking, you’ll also be able to do this on several container tracking websites.

Container Tracking Websites

There are several container tracking websites that allow containers to be tracked via an EDI/API connection to carriers, intermediaries or through AIS data. Here are some of the best container tracking websites:

Shipping Line Websites

The most commonly used method for tracking shipping containers is on the shipping line’s website. They have first hand information of container and vessel data and are typically deemed as the most accurate and official data.

3PL & 4PL Service Provider

Most multinational freight forwarders, third-party logistics (3PL) and fourth-party logistics (4PL) providers allow their customers to track their containers. As 3PL & 4PL providers usually manage complex supply chains, they typically have more sophisticated visibility tools for customers.

Benefits of Tracking Containers

Container tracking is an essential task of supply chain operators as it allows them to retrieve valuable data, with which they can plan inventory, shipments, documentation and more. Let’s take a look at several other benefits.

Increased Supply Chain Visibility

Container tracking enables better visibility of the overall supply chain, as the entire sea freight cargo flow will be visible. This allows all supply chain actors to make informed decisions.

Decision Making Management

Knowing where containers are helps with decision making, especially when there are delays that can potentially impact arrival and delivery dates. As delays are often met with higher costs, relevant parties are able to reduce them by planning for countermeasures ahead of time.

Inventory Management

Understanding the location of cargo on water through container tracking allows the destination operations to anticipate and adjust inventory levels. In some cases, air freighting cargo may be an option, if containers are experiencing delays and inventory is depleting faster than expected.

Documentation Management

It’s common for destination operations, such as custom brokers, truckers and freight forwarders to track shipping containers, as they are required to proceed with the relevant shipping documentation on time.

For example, cargo may be customs cleared in advance before arrival in some countries or carriers and forwarders may use this time to finalize amendments before the inward foreign manifest submission.

Tracking Limitations

Although there are many benefits to tracking shipping containers, there are several limitations that should be considered.

Statuses, events or milestones are updated by the carrier at specific times, which may influence decision making. Although this data is largely populated by automated systems, some manual information is processed at the back-end, which can often lead to delays.

Data quality and inaccuracy may also occur from time to time, especially when AIS signals are not good or there aren’t any AIS bases, other vessels or satellites in close proximity.

Lastly, certain carriers may only cover statuses that cover the port-to-port leg, as mainly vessel locations are tracked. Pre-carriage, on-carriage and other types of events such as customs clearance, documentation and empty container return may only be available with certain carriers when they are the party fulfilling the service.

Get Free Course Access

If you enjoyed the article, don’t miss out on our free supply chain courses that help you stay ahead in your industry.

Gerrit Poel

Co-Founder & Writer

at freightcourse

About the Author

Gerrit is a certified international supply chain management professional with 16 years of industry experience, having worked for one of the largest global freight forwarders.

As the co-founder of freightcourse, he’s committed to his passion for serving as a source of education and information on various supply chain topics.

Follow us