With rapid globalization, supply chain integration, and technological advancements, modern businesses no longer need to procure goods and services locally. Instead, they have the ability to adopt a global sourcing strategy.

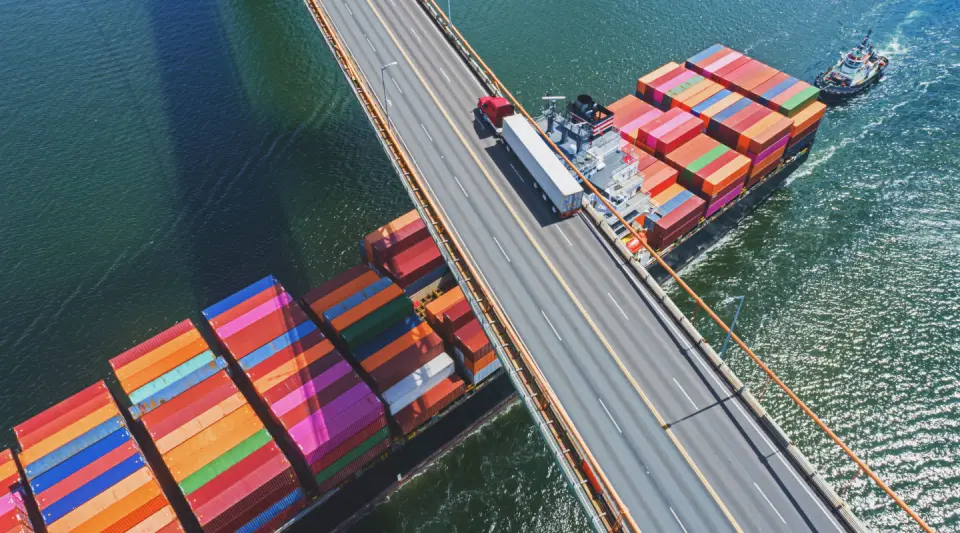

Global sourcing is the process of procuring goods and services partly or exclusively from suppliers in different countries, regions, or continents. Today, many small and medium-sized enterprises (SMEs) and large multinational companies (MNCs) reap the benefits of modern transportation infrastructures and favorable global trade policies to diversify their supplier base.

The publication Global Sourcing Strategy and Sustainable Competitive Advantage by Masaaki Kotabe and Janet Y. Murray postulates that global sourcing is now critical to supply chain efficiency, business availability, and cost optimization.

This article aims to further explore the reasons why companies plan to source globally and what logistical aspects they need to consider. We’ll also highlight the difference between global and local sourcing, as well as the key benefits and drawbacks that companies face.

What Is Global Sourcing?

Global sourcing can be defined as the strategic procurement or acquisition of goods and services from suppliers in different countries and regions. The core objective of procuring globally is to standardize quality, leverage economies of scale, lower overall costs, and increase speed to market.

Many companies seek to reap other lucrative benefits that include accessing resources or expertise that may not be available locally and establishing a diversified portfolio of suppliers.

As enticing as these benefits sound, not every company can successfully adopt this strategy. Global sourcing comes with several challenges that businesses must overcome. These challenges range from meeting regulatory and compliance requirements to understanding the intricacies of supply chain complexities.

The successful adoption and implementation of global sourcing relies on various internal and external variables that must be addressed proactively.

What Type of Industries Source Globally?

While global sourcing is available to all market sectors and businesses, it’s most commonly used by the manufacturing, technology, and retail industries. These sectors heavily rely on materials, goods, and services from global suppliers, to meet their production and operational needs.

For instance, a car manufacturer procures various components from different countries, due to market expertise and cost-effectiveness. Similarly, power plants often source coal and other resources that might not be locally available from other countries to ensure continuous production.

Below is a list of other industries that take advantage of global sourcing:

- Aerospace

- Automotive

- Consumer Electronics

- E-commerce

- Fashion

- Food & Beverage

- Furniture

- Manufacturing

- Retail

- Technology

Global Sourcing vs Local Sourcing

While global sourcing takes advantage of procuring goods and services from suppliers globally, local sourcing limits sourcing to within the same city, state, or country. As a result, local sourcing typically benefits from less complex supply chains, reduced transportation costs, and quicker turnaround times.

However, it’s important to note that locally sourced goods and services may be more expensive due to limited supply, higher production costs, and other factors. Secondly, local suppliers may not have the same level of expertise as their global counterparts.

Companies typically choose global sourcing over local sourcing to optimize costs by leveraging economic disparities, such as high currency conversion and low labor costs. Some even source goods and services from other countries, especially developing ones in Asia, Africa, and South America.

Global sourcing also provides access to broader markets with larger supplier pools offering competitive prices. Compared to local sourcing, having a global supplier base can lead to longer and more complex supply chains, which typically result in high transportation costs.

Logistical Aspects of Global Sourcing

When companies source globally, they must typically deal with longer and more complex supply chains highly susceptible to delays, security threats, and other issues. In essence, the longer the distance between suppliers and businesses, the higher the lead time for transportation, production, and other processes.

The increased distance and additional supply chain-related complexities can also increase the overall procurement costs, mainly when suppliers use multiple modes of transport to deliver cargo (sea, rail, truck, and air freight).

Companies opting for global sourcing often partner with a variety of suppliers, service providers, and carriers to meet their supply chain demands (speed, cost, and capacity). On the other hand, this practice may have contrasting challenges when it comes to sourcing services.

The logistical aspect of physically relocating human resources is a huge hurdle to overcome, especially when it involves people with families. Moreover, businesses procuring physical or online services globally may be required to learn the various labor laws and other regulations before entering into an agreement.

By proactively understanding the logistical aspects of global sourcing, companies can maximize procurement efficiency and mitigate any underlying risks.

Benefits of Global Sourcing

Global sourcing offers several lucrative benefits to businesses and suppliers. Let’s explore these benefits in more detail below.

- Economies of Scale – Businesses with multiple international branches can leverage global sourcing to centralize procurement and order in larger volumes to reduce the overall costs of goods and services and increase net revenue.

- Standardized Quality – By sourcing goods and services globally, companies can standardize quality across all suppliers. Quality standardization is incredibly difficult in local sourcing, as different regions vary in expertise, capabilities, and product or material quality.

- Supply Chain Control – Global sourcing can give companies more control over their supply chain by streamlining procurement and transportation operations. Moreover, this ensures a steady flow of raw materials, products, or other commodities, and improves control over fulfillment timelines, product or service quality, and overall operations.

- Material Accessibility – It can provide companies access to materials and products that may not be available locally. In turn, this can accelerate growth and enable continuous innovation when developing new products or improving product quality. Access to rare materials can also give them an edge in their target markets.

- Diversification of Skill Sets – With global sourcing, companies can outsource services to talents specializing in different skill sets. They can also leverage expertise that may not be available locally to drive innovation and enable diversification.

- Speed to Market – It also allows businesses to leverage multiple time zones to enable round-the-clock operations. This practice can also reduce time to market (TTM) for new products and services. For instance, companies can outsource customer services to other countries to enable 24/7 availability. This is also referred to as business process outsourcing (BPO).

Drawbacks of Global Sourcing

While there are a wide array of benefits, there are also various drawbacks that need to be considered. We’ll take a closer look at them in the following section.

- Quality Assurance – When sourcing goods and services, quality assurance is one of the biggest challenges businesses face. Varying production standards, quality control measures, and capabilities may affect consistency, efficiency, and process standardization.

- Culture & Language Barriers – Another major challenge businesses face is establishing and successfully implementing a global sourcing strategy due to language barriers and cultural differences. Effective communication is key to collaboration in complex supply chain environments. Language barriers and other cultural differences can hinder progress and overall performance.

- Supply Chain Disruptions – Local supply chains are easier to monitor and control. In contrast, complex global supply chains can be challenging to reroute quickly, especially due to disruptions caused by logistics issues, market fluctuations, natural disasters, and production delays. Similarly, travel restrictions and border closures impacted the availability of global talent with specialized expertise.

- Additional Costs – Global sourcing is highly susceptible to currency fluctuations, as businesses procure goods and services from different markets. Therefore, they must deal with currency fluctuations in procurement, transport, operations, and other aspects. Global sourcing also incurs additional costs in the form of taxes, customs duties, and import tariffs.

- Sourcing Locations – Sourcing locations can vary in infrastructure quality, logistical capabilities, time zones, and geography. All these factors can impact a company’s supply chain due to process inefficiencies, transportation delays, and communication challenges. For instance, procuring goods from multiple countries can decrease the speed to market, if processes are not managed efficiently.

- Regulatory Compliance – Countries vary in terms of regulatory compliance obligations, trade policies, customs procedures, and other aspects. Some sourcing locations may require additional documentation or licenses. Failure to meet their regulatory requirements often leads to financial and legal consequences.

Considerations for Sourcing Globally

Companies that plan to source globally are required to identify potential suppliers in different countries, conduct thorough supplier evaluations, establish robust communication, and secure reliable logistics providers.

There are also other aspects that businesses should consider when adopting a global sourcing approach, which we will further explore below.

Supply Chain Robustness

Global sourcing requires effective risk management through meticulous vendor selection, managing logistics providers, and complying with regulatory policies. Successfully establishing a robust supply chain can significantly impact the company’s overall operational and financial performance.

Besides having a diversified portfolio of vendors, companies should also seek to establish efficient transportation routes and work with reliable logistics companies. An effective way to ensure this is by establishing and enforcing standard operating procedures, managing key performance indicators (KPIs), and launching tenders for transportation & logistics services.

Supplier Management

Effective supplier management is crucial for establishing and sustaining a resilient supply chain. Companies must thoroughly assess vendors and suppliers in different countries to ensure adherence to quality, capacity, and capability.

They should also measure performance KPIs, including on-time delivery, order fulfillment rate, quality defect rate, supplier performance ranking, lead time variability, and more.

Procurement Practices

To foster an efficient supply chain, companies should establish comprehensive procurement practices to optimize cost efficiency, lead time, and other performance metrics. They should also establish robust bidding processes with clear timelines, deliverables, and quality expectations. This ensures that vendors are compliant with ethical and operational guidelines.

Technologies

With the influx of new platforms, software, and equipment, the supply chain industry has transformed in recent decades. In light of this transformation, companies looking to adopt global sourcing practices should proactively establish an infrastructure with proper communication channels, logistics software, and other essential solutions to digitize procurement operations.

Examples include Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) software. It’s also advantageous to work with logistics providers who have Transport Management Systems (TMS), that can integrate with ERPs and other platforms.

These tools offer real-time tracking and advanced data analytics that can provide actionable insights to improve decision-making and further refine global procurement practices.

Cost Optimization

Although global sourcing offers economies of scale, it doesn’t necessarily guarantee profitability. In many cases, local sourcing may bring the same quality of goods and services at a lower price point due to less distance, fewer logistical challenges, and other benefits.

Conversely, global sourcing can reduce labor and procurement costs, allowing companies to profit, even with additional transportation costs and lead times. Therefore, it’s important that companies compare procurement practices thoroughly to optimize cost and efficiency and ensure compliance with local or international regulations with regard to taxes, tariffs, compliance, and more.

Get Free Course Access

If you enjoyed the article, don’t miss out on our free supply chain courses that help you stay ahead in your industry.

Gerrit Poel

Co-Founder & Writer

at freightcourse

About the Author

Gerrit is a certified international supply chain management professional with 16 years of industry experience, having worked for one of the largest global freight forwarders.

As the co-founder of freightcourse, he’s committed to his passion for serving as a source of education and information on various supply chain topics.

Follow us