Converter dollies are among the most important pieces of equipment in the trucking industry. More specifically, they are coupling devices equipped with a fifth wheel and are designed to connect multiple trailers to a semi-truck.

Converter dollies are typically available in single-axle, tandem-axle, or tri-axle configurations. Tandem axle dollies feature two sets of axles positioned towards the rear end of the unit with one set of axles immediately behind the other.

They enable trailers to remain stable at high speeds and allow them to carry more weight. On the other hand, tri-axle dollies are commonly used to transport large machinery and other heavy freight.

In the highly competitive trucking industry, convertor dollies play two crucial roles. First and foremost, they allow truckers to convert their trucks into longer combination vehicles (LCVs), enabling them to haul doubles and triples. Secondly, they serve as a viable alternative to fifth wheels and enable truckers to haul semi-trailers without them.

In this article, we’ll talk about the main components of a converter dolly and explore the different types available in the market. We’ll also explain the key applications of converter dollies and a simple guide to dolly connection and disconnection.

Types of Converter Dollies

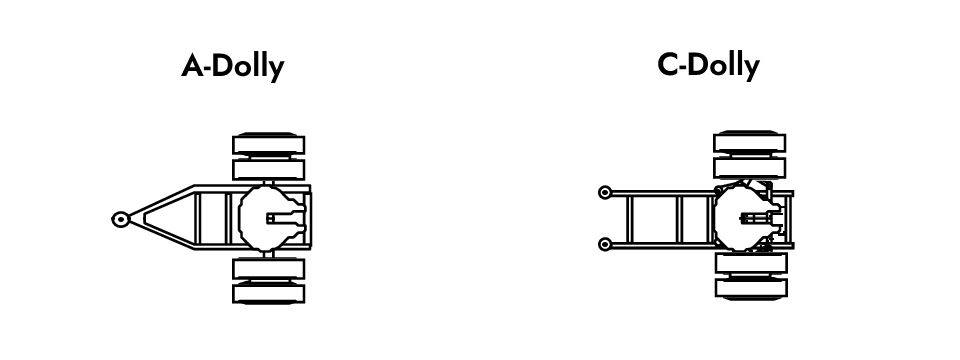

Today, you can find two types of converter dollies in the market with both types varying in the number of axles in their design. The key factor separating both types is the drawbar, which provides a solid coupling between the hauling vehicle or trailer and its hauled load.

We’ll dive deeper into the two converter dolly types by explaining their design, and axle configuration, as well as their pros and cons.

A-Dolly

An A-dolly is a type of converter dolly equipped with 1 to 3 axles and a single drawbar with a centered coupling. The key benefit of this dolly type is enhanced flexibility when transporting large and heavy cargo on routes with multiple turns.

However, the main drawback of an A-Dolly is that trucks may find it more difficult to handle and maneuver, as the trailers are highly susceptible to moving.

C-Dolly

A C-dolly is a type of converter dolly equipped with 1 to 3 axles and two separate couplings side-by-side. The key benefit of this dolly type is enhanced trailer stability and safety.

However, C-dollies are not as flexible as their counterparts. Therefore, they are not suitable for routes with multiple or narrow turns.

Converter Dolly Parts & Components

Despite being a relatively small piece of equipment, a converter dolly is made of various functional parts and each of them plays an essential role. In this section, we’ll cover the main parts and components:

- Axle – An axle is a shaft that is equipped with a pair of wheels on each end. You’ll commonly find converter dollies with single axles, tandem axles (2 axles), and tri-axle (3 axles) in today’s market. The more axles a dolly has, the more weight it can support and the larger the turning radius it has. Moreover, more axles also provide more stability on the road, especially when moving heavy freight.

- Brakes – Trailers and converter dollies are equipped with air tanks filled by an emergency supply line from the tractor. Air brakes are anti-lock braking systems that use compressed air to slow down the wheels on a dolly.

- Fifth Wheel – A fifth wheel is a U-shaped coupling device that connects a semi-trailer to a tractor to move as a single unit. In that context, the fifth wheel on the dolly is designed to lock and secure itself to the kingpin of a trailer.

- Drawbar – A drawbar is a structure found on a dolly’s front section that connects the pintle hitch behind the connecting vehicle or trailer. Drawbars are typically made of high-quality steel to maintain their structural integrity while pulling heavy cargo.

- Lights – The United States Department of Transportation (DOT) requires converter dollies to be equipped with lights, turn signals, and reflective devices at the rear so other motorists can clearly see that the truck is hauling doubles or triples.

- Suspension – Converter dollies are equipped with air or spring suspension systems. Air shock absorbers are lighter and more convenient to set up. Meanwhile, coil springs absorb shock better, making them more suitable for poor road conditions.

Converter Dolly Dimensions

Converter dollies vary in length, width, and height, depending on the manufacturer. In the table below, we’ll cover some basic dimensions in relation to their axle configuration.

| Single Axle Dolly | Tandem Axle Dolly | Tri-Axle Dolly | |

| Overall Length | 9 to 13 feet | 16 to 20 feet | 20 to 25 feet |

| Overall Width | Approx. 8.5 feet | ||

| Overall Height | Approx. 4 feet | ||

As seen in the table above, the more axles a converter dolly has, the more it contributes to your overall vehicle length. As such, it is important to select a dolly with the right balance between gross weight capacity and the maximum overall length of your vehicle.

Applications of Converter Dollies

Converter dollies are a valuable asset to any trucking company’s or owner-operator’s equipment. Below are some of the key applications they serve.

Increases Capacity

The most important function of a converter dolly is to increase the cargo capacity of a truck by converting it into a longer combination vehicle (LCV). In other words, truckers can equip their trailers with dollies to haul doubles (two trailers) and triples (three trailers) simultaneously.

For example, a trucking company can transport multiple empties (a trailer without loads), to a drop yard and enhance drop-trailer services for improved efficiency and profitability.

Similarly, another trucking company can transport up to three trailers worth of cargo in a single trip instead of engaging three separate trucks, thereby saving on time and fuel bobtailing or driving dead miles when hauling one load at a time.

Reduces Maintenance & Repairs

By hauling multiple trailers, trucking companies can save thousands of dollars yearly on fuel, maintenance, repairs, and other types of truck expenses. Hauling loads with LCVs is a great way to maximize truck and trailer utilization and reduce the overall cost per mile.

It’s also important to note that using converter dollies reduces the need to procure multiple tractors to transport trailers. It also requires hiring fewer drivers to move the same load.

Allows Load Versatility

With converter dollies, truckers can attach different types of semi-trailers to the same tractor, including flat-bed trailers, reefers, lowboys, tankers, and step-deck trailers. This setup enables drivers to haul various types of cargo in a single trip, saving time and money.

However, companies need to proactively check if the types of trailers are compatible with each other and whether they comply with state and federal regulations.

How to Connecting & Disconnecting a Converter Dolly

A significant aspect of hauling doubles and triples involves learning how to connect and disconnect a converter dolly, in order for you to hook and unhook trailers easily. We’ve shared a simple step-by-step guide to explain each process individually that you can follow below.

Connecting a Dolly to the Truck or Trailer

- To connect a dolly to a truck, you first need to bring the tractor or trailer in line with the dolly. Make sure that you do this on level ground with enough space.

- Once the dolly is in line, slowly pull it towards the connecting unit’s hook hitch and attach the drawbar pintle.

- Once attached, make sure to lock the ring to hold the dolly in place before attaching the chains on both sides of the hook.

- Next, connect the dolly chains on each side of the hitch.

Connecting a Trailer to the Dolly

- To connect a trailer to the dolly, adjust the semi-trailer’s landing legs and slowly drive the truck that has the dolly connected at the vehicle’s rear in reverse until the fifth wheel aligns to the trailer’s kingpin.

- After checking alignment, reverse slowly until the kingpin is latched into the locking jaws of the dolly’s fifth wheel.

- Then, connect their air supply and electrical lines.

- Once you have visually confirmed the coupling, set your truck to the forward drive gear and perform a tug test to confirm that your connection is secured.

- Repeat the steps in the section above and this section when connecting your third trailer.

Disconnecting a Trailer and Dolly

- Ensure that you are parked on leveled and solid ground, with plenty of space.

- Lower your trailer’s landing leg close to the ground but not all the way as you would want to avoid lifting both your trailer and the converter dolly off the ground.

- Then, disconnect the air supply and electrical lines before releasing the locking jaws on the fifth wheel of your dolly.

- Once your connections have been disconnected, you may shift your truck to forward gear and slowly move your vehicle forward until the trailer has uncoupled from the converter dolly.

- The next step would be to uncouple your converter dolly. Your first step would be to remove the chains.

- Unlock the ring securing the pintle and lift your converter dolly to remove it from the hitch of the coupled truck or trailer.

- Finally, store your converter dolly safely away before removing the next trailer.

Get Free Course Access

If you enjoyed the article, don’t miss out on our free supply chain courses that help you stay ahead in your industry.

Andrew Lin

Co-Founder & Writer

at freightcourse

About the Author

Andrew is a multi-business owner with over 12 years of experience in the fields of logistics, trucking, manufacturing, operations, training, and education.

Being the co-founder of freightcourse has given him the ability to pursue his desire to educate others on manufacturing and supply chain topics.

Follow us