The American Trucking Associations (ATA), the largest national trade association for the trucking sector in the United States, highlights that the trucking industry plays a crucial role in transporting more than 70% of all freight across the country.

Today, almost every sector of the economy relies on trucking companies to move raw materials, semi-finished and finished goods, equipment, and more. If the trucking industry encounters any form of disruption, the supply of essential commodities throughout every industry, from construction to retail, manufacturing, and utilities, would be heavily impacted.

The Hours of Service (HOS) regulations serve as an important framework for the trucking industry as they prioritize safety by preventing driver fatigue and reducing the risk of accidents. The mandating of rest periods and setting limits on driving hours ensures the well-being of drivers while ensuring compliance in the industry.

In this article, we’ll dive deeper into the Hours of Service set by the U.S. Department of Transportation (DOT) and explain its purposes and regulations. We’ll also delve into topics around compliance and share effective tips truckers can use to maximize their HOS.

What Is DOT or FMCSA Hours of Service (HOS)?

Hours of Service (HOS) is a regulatory framework with the aim of governing the working hours and rest periods of commercial motor vehicle (CMV) drivers. The HOS regulations are designed to promote safety on the roads by preventing driver fatigue and ensuring drivers receive adequate rest.

In essence, the Hours of Service (HOS) refers to the maximum allowable working hours (or service hours) enforced by the Federal Motor Carrier Safety Administration (FMCSA), an agency under the US Department of Transportation (DOT).

HOS regulations are ultimately enforced to improve road safety. They establish time limits drivers must follow (by setting a maximum time limit) to legally operate commercial motor vehicles (CMVs) on roads and highways.

Purpose of Hours of Service (HOS)

Below are the main reasons the Hours of Service framework was established in 1930 when the trucking industry was still in its infancy:

- Improving Driver Well-Being – Operating a truck is significantly more challenging than driving smaller vehicles like cars as truckers need to be on constant alert. Moreover, truckers are often on the road for hours on end, which can lead to fatigue. The main purpose of HOS is to minimize or prevent overworking to ensure drivers take care of their physical and mental health.

- Protecting Road Users – Fatigue contributes to half of all fatal road accidents while 30-40% of all heavy vehicle accidents are related to driver fatigue. It leads to slower reactions, drowsiness, and poorer estimation, resulting in an increased risk of collisions. HOS helps reduce driver fatigue and plays an indirect but crucial role in preventing accidents.

- Ensuring Fair Competition – HOS regulations also foster a level playing field for carriers and owner-operators, irrespective of the market they serve. These regulations establish a standardized maximum time limit that their driver must adhere to, ensuring fair competition within the trucking industry.

- Enforcing Employee Rights – HOS also protects drivers and employees from company exploitation by setting a maximum number of hours drivers may operate a commercial vehicle. This ensures a better work-life balance and protects employee rights.

Hours of Service (HOS) Regulations

As we covered earlier, strict adherence to Hours of Service regulations is imperative for truckers to operate commercial vehicles lawfully on United States roads and highways.

In the following sections, we’ll cover aspects pertaining to the applicability of HOS regulations and also highlight certain exceptions. While we’ve provided a comprehensive guide below, we encourage you to also read the Summary of Hours of Service Regulations from the Federal Motor Carrier Safety Administration (FMCSA).

Commercial Motor Vehicle Transporting Cargo

Below is a summary of the Hours of Service Regulations for commercial motor vehicles that are transporting cargo.

- FMCSA mandates all drivers to legally operate vehicles up to a maximum of 11 hours as long as they have had 10 consecutive hours off duty.

- CMV drivers who are commencing their shifts after 10 consecutive hours off duty are not allowed to operate their vehicle past the 14th hour. Additionally, these 14 hours must also include off-duty time taken in between.

- FMCSA requires drivers to take an uninterrupted 30-minute break after driving for 8 hours. To comply with this rule, drivers can take breaks in different ways. For instance, a driver can take a 30-minute break on duty by not driving. Similarly, they can choose to rest during their off-duty period or on a sleeper berth in their vehicle.

- Drivers cannot operate their vehicles after 60 hours on duty for 7 days in a row (applicable for drivers with off days) or 70 hours for 8 days in a row (applicable for drivers operating 7 days a week). They can wait to utilize recap hours the following day or must take a minimum of 34 continuous hours off duty before restarting their duty.

- Under the sleeper berth provision, drivers are permitted to split their required 10-hour off-duty period. However, they need to have one off-duty period of a minimum of two hours in or out of their sleeper berth and a minimum of seven continuous hours in their sleeper berth. All off-duty combinations must add up to a minimum of 10 hours. Besides, if drivers use the sleeper berth pairings together, it cannot count against the maximum 14-hour driving window.

- In the event of adverse driving conditions, drivers can extend the 11-hour maximum driving limit up to two hours. They can also extend their 14-hour driving window by the same period.

- Drivers are exempt from 395.8 and 395.11 requirements that mandate them to record their duty status manually and submit supporting records (itinerary, expense receipt, communication record, etc.) if they operate within a 150-air-mile radius of their reporting location. Drivers are also exempt from these requirements if their maximum duty period doesn’t exceed 14 hours. However, they must report and return to their work location within the 14-hour window and stay within a 150-air-mile radius.

Commercial Motor Vehicle Transporting Passengers

Commercial motor vehicle drivers transporting passengers are also subject to HOS regulations as outlined below.

- FMCSA mandates all drivers transporting passengers to operate vehicles up to a maximum of 10 hours as long as they have had 8 consecutive hours off duty.

- Drivers starting their shift after 8 consecutive hours off duty cannot operate their vehicles past 15 hours. Similar to CMV hauling loads, the 15-hour period doesn’t include off-duty time.

- Drivers transporting passengers must adhere to a 60/70-hour limit, meaning they cannot drive after 60 or 70 hours on duty in 7 or 8 days in a row.

- Drivers using sleeper berths must have at least 8 hours of break in the berth. However, they can split the sleeper berth time into two periods – each with a minimum of two hours. All combinations must add to at least 8 hours. For example, if a driver chooses to rest for three hours in their first rest period, they must spend at least five hours in their second rest period.

- In the event of adverse driving conditions, drivers can extend the 10-hour maximum driving limit up to two hours. They can also extend their 15-hour driving window by the same period.

- Drivers are exempt from 395.8 and 395.11 requirements if they transport passengers within a 150-air-mile radius of their reporting location. Drivers are also exempt from these requirements if their maximum duty period doesn’t exceed 14 hours. However, they must report and return to their work location within the 14-hour window and stay within a 150-air-mile radius.

Hours of Service (HOS) Exemptions

FMCSA does offer flexibility to drivers hauling cargo or transporting passengers with the following exemptions:

- Short-haul drivers that operate within a 100-air-mile radius are exempt from the 30-minute break rule. Short-haul drivers operating non-CDL vehicles within a 150-air-mile radius are also exempt from this rule.

- Drivers can extend the 14-hour driving window to 16 hours when transporting loads over short distances (short-haul trucking). However, they can only do this once every seven consecutive days. Certain conditions apply for this exemption to be applicable. For instance, cargo-hauling drivers must return to their reporting location and be released from their duty for five days in a row. Or, the driver should get released from duty at their normal reporting location within 16 hours of their shift following 10 consecutive hours of service. Finally, drivers who opt for this exemption cannot use the non-CDL vehicle 150 air-mile exemption in the first point.

- Drivers who transport only within a 150-air-mile radius may extend their duty window from 14 to 16 hours twice within 7 consecutive days. Moreover, they are not required to obtain a CDL to operate their vehicle.

- In emergencies, CMV drivers are exempted from several HOS regulations. However, emergencies don’t include accidents or mechanical failure. Instead, these are conditions declared by POTUS, state officials, or the FMCSA. Examples include hurricane warnings, pandemic outbreaks, earthquakes, etc.

Who Does the Hours of Service (HOS) Apply To?

HOS regulations apply to most commercial motor vehicle drivers operating on US roads and highways. CMVs are vehicles used for business purposes and are typically involved in interstate supply chain processes. Below is a brief description of these vehicles.

- CMVs that weigh a minimum of 10,001 pounds without any load. This means that they have a minimum gross combination weight rating of 10,001 pounds.

- CMVs that are designed to transport at least 16 passengers, including the driver.

- Any vehicle transporting hazardous vehicles using placards qualifies as a CMV.

- Any vehicle used for transporting freight or fare-paying passengers qualifies as a CMV.

Staying Compliant With Hours of Service (HOS)

Hours of Service is one of the strictest transportation regulations in the United States. If any law enforcement finds trucker drivers or companies violating HOS regulations, they can penalize them heavily and even shut down their operations.

For instance, if you drive past the maximum time limit, you could be forced to park your truck on the roadside or a terminal nearby until you accumulate enough off-duty time to meet the compliance. Depending on the situation, this could affect your bottom line.

Officers can assess fines between $1,000 and $16,000 on average. The situation worsens if you’re caught violating HOS regulations while carrying hazardous material. In this case, you could be fined over $75,000.

Carriers use the following solutions and strategies to remain compliant with DOT or FMCSA HOS regulations and prevent shutdowns and fines:

- Utilize ELDs – Drivers can use their electronic logging devices (ELDs) to record working and rest times. Carriers can also keep track of their HOS with high accuracy. Many carriers with older trucks are rapidly adopting ELDs (despite qualifying for ELD exemptions) as it improves tracking and minimizes the risk of violations.

- Keep Up-To-Date On HOS Regulations – By staying up to date with HOS regulations, carriers and drivers can proactively learn about any changes posted by DOT or FMCSA and avoid getting caught violating them. We recommend checking for updates on FMCSA’s website.

- Attend Regular Training – The most reputable carriers attend and conduct regular HOS training sessions to remind drivers of the dos and don’ts of maintaining compliance with the authorities.

- Plan Routes Ahead of Time – Most HOS violations are caused by poor planning. By planning efficient schedules, routes, and rest periods, you can complete deliveries faster and avoid running the clock.

- Maintain A Healthy Lifestyle – Rest is an essential part of trucking. It’s one of the main reasons HOS regulations were set in the first place. So, one way to remain compliant with the authorities is to avoid pushing yourself and taking risks that could prompt you to violate the time limits for short-term gains.

Tips For Maximizing HOS

Fortunately, there are ways you can boost your productivity and maximize your hours of service while remaining compliant. Below, you’ll find some useful tips that you can adopt as a trucking company, owner-operator, or truck driver.

Transport Management System (TMS)

Transport management systems are logistics software solutions that can help truckers optimize their supply chains by allowing them to plan and execute their trips more efficiently.

By using these platforms, you can improve your transit schedules and plan better routes. Doing so will improve your overall productivity by saving time, which you can use to complete more trips in your regular duty period.

Load Boards & Digital Freight Matching (DFM) Platforms

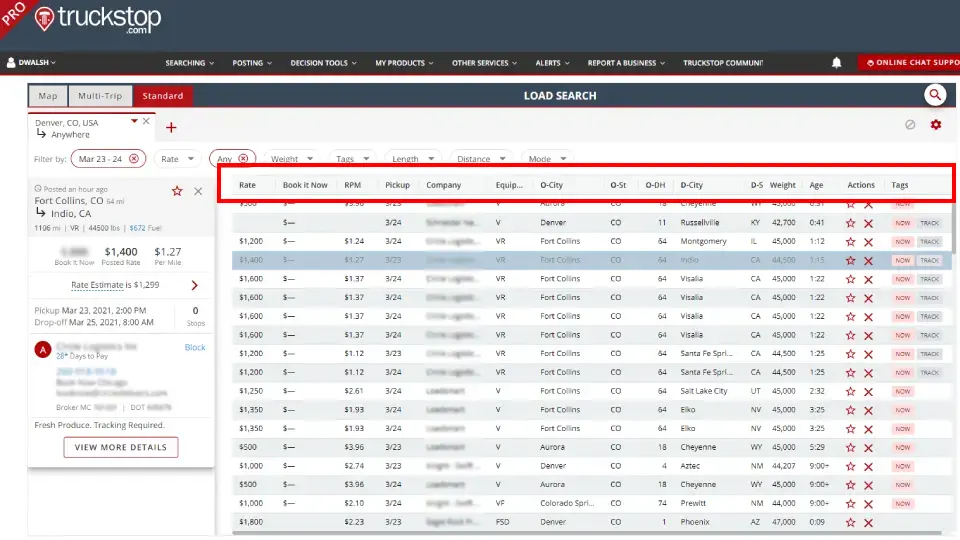

Load boards are online marketplaces where truckers can communicate with brokers and shippers/receivers about available jobs. Similarly, digital freight matching platforms allow truckers to haul loads according to their trucking capacities and routes. Using these solutions, carriers, and owner-operators can do a lot more than just secure loads.

DFM platforms utilize advanced algorithms and machine learning to provide route options that carriers can select from that best suit their driver’s remaining hours of service. As such, carriers can maximize their schedules and routes while ensuring they don’t violate HOS regulations.

Truck Terminals

Truck terminals are one of the most important facilities in the trucking industry. They’re the go-to stopover facility truck drivers use to rest once they hit their hours of service. Modern terminals are often equipped with restrooms, restaurants, maintenance facilities, and other amenities that can help truckers save valuable time and improve productivity.

Moreover, they also serve as a cross-docking station where truckers can unload cargo from inbound vehicles and load them onto outbound vehicles. Additionally, these terminals can be used as an operating base for truckers in the event that a carrier’s clients are located within close proximity of a terminal.

Drop Yards

Drop yards are another important facility truckers use to improve their supply chain processes by proactively dropping multiple trailers and picking them up for deliveries. Most truckers do this by hauling doubles or triples to the yard and uncoupling the additional trailers for future use.

With this trucking method, they can minimize bobtailing and backhauling distances, both time-consuming processes that can lead to HOS violations and safety violations as well. Simply put, drop yards give truckers more time to deliver cargo or allow them to make more deliveries than they would have without them.

Drop Trailer & Drop-and-Hook Services

Drop trailer and drop-and-hook services are among the most popular trucking methods carriers use to maximize their hours of service. Instead of waiting for shippers/receivers to perform live loading, they simply uncouple their trailers at the facility and pick them up another time. With this strategy, they can focus solely on transporting cargo and make more deliveries in a single shift.

Opt To Haul No-Touch Freight

No-touch freight is a trucking method in which drivers don’t handle cargo. In other words, shippers and receivers are responsible for loading and unloading cargo from trucks.

With this strategy, drivers can focus all of their energy on hauling cargo instead of spending additional time handling cargo partially or independently. However, carriers need to coordinate closely with the shipper or receiver to avoid unnecessary idling in the event of manpower or equipment shortages.

Slip Seating

Slip seating is a trucking practice in which multiple drivers share a truck. Carriers that adopt this practice can avoid relying on one driver to operate a truck and increase their equipment utilization by hauling cargo around the clock.

With slip seating, drivers that share a common truck can enjoy a better work-life balance. They’re less fatigued than their counterparts and more productive. However, there are also downsides to this practice that need to be considered.

First-Come-First-Serve Arrangements

First-Come-First-Serve (FCFS) in freight shipping is a cargo handling practice that allows truckers to load or unload cargo following their arrival. With this practice, truckers don’t have to set appointments and wait in line until their turn arrives.

As a result, they can save time and efficiently utilize their Hours of Service. Since they don’t have to come in at a specific time, they can choose the hours with the least congestion on the roads or at the facility.

However, if they don’t plan it right, this strategy can backfire on their HOS utilization. The last thing you want is to arrive at a facility practicing FCFS scheduling only to see a long queue of trucks ahead of you.

Fleet Benchmarking

Fleet benchmarking is the process of leveraging driving patterns data and telematics to evaluate and improve trucking operations by making necessary adjustments. Truckers can use this strategy to plan better routes and schedules, minimize idling, and gain visibility into the best practices that can improve productivity and maximize HOS.

By benchmarking against other fleets within the same niche or against past data, carriers can have better insights into areas that they can target to improve and reduce operating time wastage.

Get Free Course Access

If you enjoyed the article, don’t miss out on our free supply chain courses that help you stay ahead in your industry.

Andrew Lin

Co-Founder & Writer

at freightcourse

About the Author

Andrew is a multi-business owner with over 12 years of experience in the fields of logistics, trucking, manufacturing, operations, training, and education.

Being the co-founder of freightcourse has given him the ability to pursue his desire to educate others on manufacturing and supply chain topics.

Follow us