The trucking industry features a variety of heavy-duty freight vehicles, from small lorries to box trucks and large semi-trucks. No matter which trucking niche or services a carrier is specializing in, like any business, they aim to be profitable while meeting the needs of the trade.

However, a huge aspect of maximizing profitability involves minimizing waste by tackling different inefficiencies in their operations. One of the most important inefficiencies for truckers today is deadheading.

Deadhead is a common trucking term used to describe the process of driving back to base with an empty trailer after delivering a load. For any carrier, this unwanted but often unavoidable practice translates to a higher cost per mile, reduced driver productivity, and forgone profits from missed cargo-hauling opportunities.

In this article, we’ll explain deadhead and deadhead miles in detail and walk readers through their negative impact on truckers and the industry in general. We’ll also share the key reasons behind deadheading and effective strategies to minimize deadhead miles.

What Are Deadhead & Deadhead Miles in Trucking?

Semi-trucks haul various types of semi-trailers, including flatbeds, reefers (refrigerated), intermodal (containers), dumper, and lowboy trailers, to name a few. Depending on the location, market conditions, and circumstances, it’s not uncommon for truckers to deliver a load and return with an empty trailer.

In essence, deadheading is when a truck is traveling with a trailer, but without a load. This practice results in the accumulation of deadhead miles. Deadheading is an undesired practice in the trucking industry with several negative impacts, which we’ll explain in the next section.

In light of this, deadhead miles are now one of the key performance indicators carriers use to analyze and improve their routes, schedules, and other aspects of operations when doing fleet benchmarking.

Negative Impacts of Deadhead

Running trucks without a load leaves a negative impact on the business or operator because it wastes resources and contributes to unnecessary carbon emissions. Additionally, deadheading reduces overall efficiency and profitability for trucking companies, as it involves incurring costs without generating any revenue.

We’ve further elaborated on some of these reasons to get a better picture of the negative impacts.

- Fuel Consumption – When drivers haul empty trailers back to base after making a delivery, they burn additional fuel without generating any revenue. Therefore, the fuel consumed in the return trip goes into the overall cost per mile of that particular shipment.

- Hours of Service – Drivers are legally required to operate following the limits set by the Federal Motor Carrier Safety Administration (FMCSA). Deadheading eats into their hours of service (HOS) and affects their overall productivity. In other words, they spend a chunk of their shift not hauling cargo and accumulate deadhead miles in the process.

- Equipment Wear & Tear – The more miles a truck travels, the more wear and tear the tractor and trailer incurs. Deadhead miles increase the frequency of repairs and maintenance, resulting in higher operating costs for truckers.

- Environmental Harm – The more fuel a truck burns, the more greenhouse emissions it releases into the environment. Deadheading doesn’t contribute to a carrier’s revenue. Instead, it increases the amount of fuel consumption without achieving any supply chain value. So, the more deadhead miles a truck accumulates, the more greenhouse gases they release unnecessarily.

- Profit Margin – In summary, deadhead miles increase overall truck expenses and a carrier’s cost per mile – both factors that can shrink their profit margins, especially in highly competitive markets.

Understanding the Reasons Behind Deadhead Miles

Before you can employ different strategies to reduce deadhead miles, you need to understand the key reasons behind them. Let’s further explore them.

Inefficient Route Planning

Inefficient route planning is one of the common causes of unnecessary deadhead miles accumulation. In many cases, truckers have to travel several miles with an empty trailer to pick up their first or the next load.

For example, a carrier based in Burlington, Vermont, has few regular deliveries to make within a day. The driver makes the deliveries by following these delivery routes; Burlington-Richmond, Burlington-Colchester, and Essex-Burlington at the end of the day.

With a simple change in routing, the carrier can reduce deadhead miles by planning Burlington-Richmond-Essex-Burlington-Colchester. This would save one deadhead trip during the transit.

Insufficient Scheduling

Another major reason for deadheading is insufficient scheduling. For example, a carrier based in Omaha, Nebraska, has to make trips to Des Moines and Blair. The driver departs from their home base and arrives at Blair on a Monday to make a routine delivery and then returns to the base with an empty trailer.

The next day, the driver makes a delivery to Des Moines and collects another load to deliver to Blair on their way back to base. None of these trips were urgent. Therefore, the carrier could have simply asked the driver to wait till Tuesday and complete all deliveries with a single trip by following Omaha-Blair-Des Moines-Blair-Omaha.

Demand Fluctuations

Demand fluctuations are another common reason truckers accumulate deadhead miles. In some markets, there’s a low demand for backhaul trucking. As such, not every trip would have a load ready for a backhaul on time. This circumstance is fairly common during a low season.

Therefore, carriers would often have no choice but to make a delivery trip and return deadhead, especially if it means keeping their operations running with whatever loads they can secure and managing with lower profits.

Miscommunication

Finally, there are cases in which drivers have had to return to home base deadhead simply due to miscommunications. Complex schedules and processes can prompt carriers to misunderstand the dates a client requires a truck to send or pick up loads, resulting in wasted trips. In extreme cases, drivers travel deadhead miles to and from a client’s location.

6 Strategies for Minimizing Deadhead Miles

In the next section, we will be taking a detailed look at strategies that carriers can implement to reduce deadhead miles and increase efficiency in their trucking operations.

Load Boards

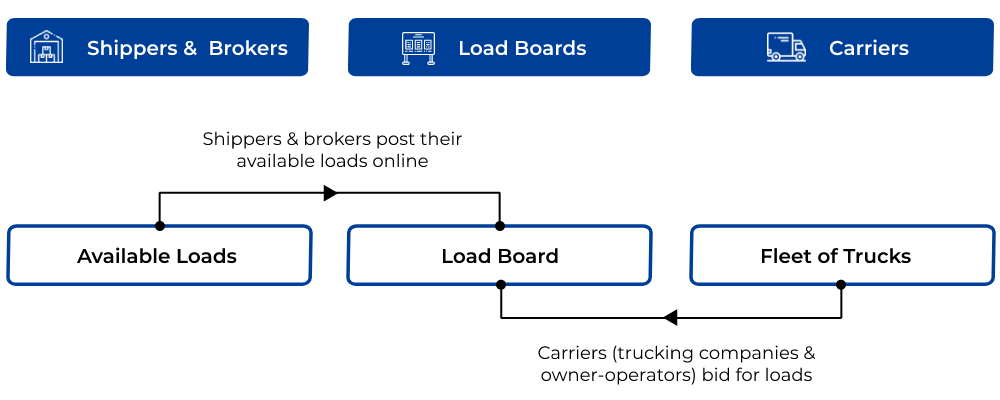

Load boards are digital platforms that allow carriers to post their services, routes, available fleet and equipment, and hauling capacities. Shippers and brokers also use these solutions to post their shipping requirements.

Load boards serve as marketplaces where both parties can connect and enter an agreement to transport goods from point A to point B. To use one, you simply have to create an account and post relevant information about your services, availability, trailer type, etc.

Once done, you can use the search tab to find jobs that meet your preferences. One of the best uses of a load board in context to deadheading is finding loads for the return route so drivers can pick them up and avoid returning to base with an empty trailer.

- Additional Resource: How to Use Load Boards

Digital Freight Matching (DFM) Platforms

Digital freight matching (DFM) platforms are more advanced versions of load boards connecting truckers with local loads digitally according to their shipping capacities, operating timelines, practices (LTL, FTL, PTL), and other factors.

These platforms leverage machine learning and AI algorithms to find the best solutions for carriers and shippers. To use a DFM platform, you simply need to register an account on your preferred solution.

Once you have access to the marketplace, you can input relevant information related to your services, and the platform will automatically match you with shippers and receivers accordingly. Most DFM platforms also allow users to integrate their transport management systems to add documentation, tracking, and administration to a centralized location.

Like load boards, DFM platforms reduce deadhead miles by finding loads for return trips. However, they can go one step further by helping you optimize route planning and scheduling as well to reduce deadhead miles between trips as well.

Transport Management System (TMS)

A transport management system (TMS) is essentially a logistics platform designed specifically for truckers to plan, execute, and optimize freight transport. It essentially provides visibility into everyday operations and helps carriers take care of essential processes, such as billing and documentation.

Other key features include load planning, load tendering, rate management, dock scheduling, and fleet management (tracking, maintenance scheduling, and more). TMS solutions can help carriers reduce deadhead miles in different ways.

For instance, the ability to track freight in real-time can help carriers proactively find loads for return trips based on the estimated delivery time and location. Similarly, they can use TMS to calculate their cost per mile and offer more flexible backhaul rates to entice shippers to opt for their services when they don’t have any loads to transport.

Drop Yards

A drop yard is a trucking facility where carriers can drop multiple semi-trailers for short-term and long-term storage. These facilities allow truckers to make multiple deliveries on a specific route without the need to drive back to home base to pick up another trailer.

While the core purpose of this strategy is to minimize bobtailing, there are situations where carriers may need to switch their semi-trailer to another type to meet load requirements.

For instance, a truck hauling a flatbed trailer may need to switch to a dry van trailer as the shipper requires protection of freight from direct sunlight. Truckers can save fuel, reduce the rate of wear and tear, improve productivity, and reduce their overall cost per mile by shaving off deadhead miles back to base just to make the trailer change.

Drop-and-Hook

Drop-and-hook trucking is a popular method that involves a driver dropping off a trailer at a client’s facility and picking up a loaded trailer. The average wait times for drop-and-hook trucking are typically less than an hour, which is significantly less than live loading.

Therefore, drivers can make more deliveries during their HOS and optimize productivity. How does this minimize deadhead miles? Firstly, drop-and-hook trucking simplifies scheduling for all parties – drivers, carriers, and shippers.

For instance, shippers can load trailers at their convenience instead of worrying about detention. Similarly, carriers can schedule pickup and drop-off according to their schedules and plan multiple trips along the same route, which can drastically reduce deadheading and bobtailing.

Secondly, since truckers practicing drop-and-hook avoid loading and unloading processes, they can increase their productivity and compensate for losses incurred by deadhead miles by making more trips during their HOS and increasing the profit margin.

Truck Terminals

Truck terminals are stopover facilities where truckers can park their trucks temporarily following their shifts or layover instead of returning to base. Using these facilities, drivers can do a lot more than take advantage of facilities, such as restrooms, eateries, and truck maintenance services.

When they don’t have backhaul loads, they can stay at terminals in a specific area instead of wasting time, energy, and fuel driving back to base with an empty trailer.

Get Free Course Access

If you enjoyed the article, don’t miss out on our free supply chain courses that help you stay ahead in your industry.

Andrew Lin

Co-Founder & Writer

at freightcourse

About the Author

Andrew is a multi-business owner with over 12 years of experience in the fields of logistics, trucking, manufacturing, operations, training, and education.

Being the co-founder of freightcourse has given him the ability to pursue his desire to educate others on manufacturing and supply chain topics.

Follow us